Blue Moon Retarder Proofer Cabinets and Criolla Chocolate Cabinets feature a new 5" control: V‑LINK. This now replaces the C‑TOUCH control.

It integrates all technical breadmaking recipes as standard, and guarantees product integrity and quality thanks to its precise, adaptive management of

temperature, humidity and air flow according to the chosen program. It also optimizes dough texture, aroma and taste.

Features:

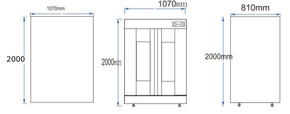

Specifications:

Size of Trays: 400 x 600 mm

No. of levels: 20

No. of supports per level: 1

Total no. of supports: 20

Spacing out of levels: 63 mm

Level depth: 600

Tray entry direction: 400

Refrigerating unit: 1 refrigerating unit of 1/4 CV

No. of doors: 1

Refrigerating capacity at -10°C: 0.45 KW

Refrigerant: R404A

External Dimensions: 560mm W x 915 D x 1990 H

Voltage: 240V ~1PH+N+T

Frequency: 50 HZ

Connecting electrical power: 0.9 KW 5A

Connection: 5 A

Warranty: 1 Year

N.B Trolley is not included, please ask us for a quote.

N.B Images are for illustrative purposes only. Specifications are subject to change without notice.

Blue Moon Retarder Proofer Cabinets and Criolla Chocolate Cabinets feature a new 5" control: V‑LINK. This now replaces the C‑TOUCH control.

It integrates all technical breadmaking recipes as standard, and guarantees product integrity and quality thanks to its precise, adaptive management of

temperature, humidity and air flow according to the chosen program. It also optimizes dough texture, aroma and taste.

Features:

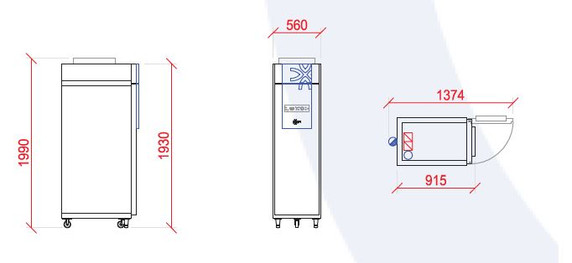

Specifications:

Size of Trays: 400 x 600 mm

No. of levels: 20

No. of supports per level: 1

Total no. of supports: 20

Spacing out of levels: 63 mm

Level depth: 600

Tray entry direction: 400

Refrigerating unit: 1 refrigerating unit of 1/4 CV

No. of doors: 1

Refrigerating capacity at -10°C: 0.45 KW

Refrigerant: R404A

External Dimensions: 560mm W x 915 D x 1990 H

Voltage: 240V ~1PH+N+T

Frequency: 50 HZ

Connecting electrical power: 0.9 KW 5A

Connection: 5 A

Warranty: 1 Year

N.B Trolley is not included, please ask us for a quote.

N.B Images are for illustrative purposes only. Specifications are subject to change without notice.